October 27, 2020

Your seat awaits

Polishing one of Chicago's architectural crown jewels

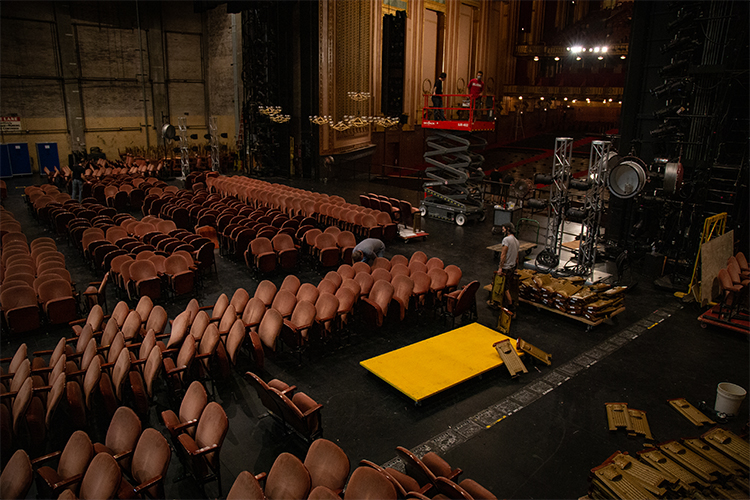

When performances resume in the Lyric Opera House, new seats will be waiting for you in the Ardis Krainik Theatre. Thanks to dedicated funding from an Anonymous Donor, this project represents an exciting step forward for Lyric's Patron Accessibility initiative. The theater will feature updated sightlines on the main floor; wider, better-lit aisles; additional wheelchair seating; and lush, state-of-the-art seats on all levels. The largest renovation in nearly two decades, the project began in 2019 and involved countless suppliers, consultants, and contractors.

A brief overview of the seating project from Lyric's General Director, President, & CEO, Anthony Freud.

While Lyric Opera of Chicago was not founded until 1954 (as the Lyric Theatre of Chicago), the beautiful Civic Opera House—now known as the Lyric Opera House—first opened its doors in 1929 (just days before the stock-market crash, but that's another story). Because of the extraordinary nature of the building, historical accuracy was a top priority during the 2020 renovation, both in design and in maintaining the signature acoustics of the space. To assure our productions sound better than ever, we brought in Chicago-based acoustical consultants Kirkegaard Associates to advise us on the impact of our new seats and layout. The company was extensively involved in our 1996 renovation, and were instrumental in helping us lengthen the theater's reverberation time by decreasing the room's absorption.

This project aimed to improve sightlines, widen aisles, and improve access for patrons with disabilities. Our structural engineers, Klein & Hoffman, helped us achieve these goals while still preserving the architectural integrity of our theater. The largest undertaking was the modification of the concrete infrastructure of the main floor and an upper balcony entranceway. We moved numerous HVAC return air vents, eliminated the slope of the main floor cross aisle (in front of row AA), and created new concrete pedestals for our wheelchair platforms.

Renovations were originally set to begin on June 30, immediately following the final performance of 42nd Street, and conclude just before Opening Night of our 2020/21 Season in September. However, when the realities of COVID-19 came crashing down last spring, we were forced to develop multiple contingency plans to ensure the project's continuation while also protecting the health of everyone involved. The project was in a constant state of flux from March 13 through June 15, as we made adjustments to our construction and work schedules as well as to our site safety plans in accordance with city and state mandates.

After a long research process, we ultimately selected a state-of-the-art seat design with outstanding aesthetics, acoustic characteristics, and comfort made by Series Seating. The seat provides a molded foam back that offers subtle lumbar support, an ergonomically pleasing design for maximum comfort, and a patented silent seat gravity lift system that is engineered for quiet open and close. Series Seating also sets the bar for environmentally responsible manufacturing. Their facility, located outside Bogotá, Colombia, produces zero pollution and virtually no waste.

As a result of a government-mandated shutdown due to rising infection rates of COVID-19, our seating vendor stopped all production on our seats from March 24 to April 13. During this time, we worked together to implement our jointly developed contingency plans, initiating new safety procedures and manufacturing-operation changes. Once work was allowed, the production facilities ran two full, socially distanced production shifts. It also hired additional cleaning staff to continually sanitize its facilities, and implemented new employee health and safety protocols, including virus testing.

As soon as we received word that our shipment of seats was on its way to Chicago, IATSE Local 2 stagehands began removing the old seats from the main floor and balconies of the Ardis Krainik Theatre. The gilded end panels were carefully removed from each aisle seat and shipped to Series Seating’s facility in North Carolina, where they were powder coated and modified to fit our new seats. The end panels are original to the theater, and have not been touched since 1996, when they were repainted for the first time since they were installed in 1929. Originally, only every other end panel included an aisle light. The most obvious modification will be the addition of LED lights to each end panel—improving visibility and the overall safety of our walkways.

More than 3,500 old seats were packed into shipping containers to be stored at our south-side warehouse until we are able to find them a new home. From the very beginning, we knew we wanted this project to be as "green" as possible. Our various vendors, suppliers, and contractors are similarly committed to sustainable construction and business practices. Most of our construction waste is being recycled or reused, and thankfully we were able to "upcycle" our existing 288 box-seat chairs. These movable seats are being completely remade by The Furniture Shop, Inc., a south-side Chicago-based artisanal furniture refurbishing, refinishing, and upholstery firm, specializing in fine furniture preservation and repair.

As our stagehands completed the removal of the old seats from the theater, Bully & Andrews personnel began erecting protective barriers throughout the theater. All lobby floors, stairways, and walls were covered. Further, all brass fixtures were protected with bubble wrap, all artwork was removed and safely stored, and all light fixtures had their glass covers removed and stored by our stagehands for protection.

As any HGTV fan knows, even the most beautiful old homes can have their surprises and setbacks. For our house, that was finding a patch of lead paint on the main floor of the theater. After the space was cleared, we brought in a specialized team from National Decorating Service to handle the removal. This required setting up containment tents that could be ventilated with sophisticated HEPA filters and shifting other work to unaffected areas of the opera house. While the abatement team—working in full hazmat protective equipment—operated in these tents, removing the contaminated paint from the floor using grinders and filtered vacuums, Block Electric workers were installing new electrical power panels in the basement and running new wiring into the balconies. This work was required in order to accommodate the new aisle lighting and to add electrical outlets for our new technical table locations (which are in place during rehearsal periods).

During September, contractors loaded in eight concrete trucks—each weighing roughly 55,000 pounds—through the scenery and handling area.

Seeing the concrete trenching work start was both the scariest, and most rewarding portion (so far) of the project. Until then, everything we did was (more or less) reversible. For instance, if everything failed, our old seats could have been kept in place (or reinstalled in the theater) and our new seats could have been stored until we were ready to proceed. Therefore, for me, it wasn't until we not only received our new seats, removed the old ones, AND began cutting into our existing floors that we reached the point of no return.

Our concrete contractors drilled holes for updated electrical wiring and our new HVAC return air vents. With that complete, they began re-sculpting the main floor aisles and leveling out the surface using a customized concrete formula poured into prepared wooden frames. The main floor cross-aisle (formerly Row AA) was moved toward the back of the theater and four rows near the stage were adjusted to bring the slope of the lower portion of the theater to the necessary height.

By reducing the overall number of seats in the theater, we are able to accommodate larger wheelchair platforms, provide wider seats, and more legroom. The new seats from Series Seating are the most ergonomically comfortable theater seating on the market. They facilitate "active sitting," which increases blood circulation, reduces back strain, joint stiffness, and muscle strain when sitting for long periods of time.

In addition to providing a more comfortable chair, the new seating configuration on Lyric's main floor follows an offset design for improved sightlines to the stage that offers a parallel experience to the graduated seating design of the balconies.

We used a high-performance concrete, formulated specifically for this project. By increasing its durability and shortening its "cure" time, we were able to paint our new concrete floors within seven days of pouring them, and bolt our seats to these floors within two weeks of the pour.

The most obvious change you will notice upon entering the theater is the new layout of the main floor. The newly curved aisles will be brighter, wider, and more accessible. Working with our disability platforms manufacturer Staging Concepts, and many consultants and engineers, we have greatly increased our wheelchair seating. Nineteen state-of-the-art movable disability platforms will be installed throughout the theater on all floors, with the exception of the Mezzanine (which already has movable chairs). We will also have 11 additional fixed wheelchair locations, as well as 45 removable aisle seats. Patrons in wheelchairs will also no longer be relegated to "the wings" of the theater, with new platforms installed along the second, third, fourth, and fifth aisles of each floor.

In early October, our dedicated stagehands, assisted by a crew from Series Seating, began installing the new seats in the balconies. As the floors were painted, and new anchor bolts were installed, seating installation moved to the main floor.

With a final count of 3,276 beautiful new seats, we can't wait to roll out the red carpet and welcome you home to the Lyric Opera House.